Venturi Scrubber

To remove sub-micron particles from flue gas Ducon's Venturi scrubber uses a wet process utilizing high pressure drop. Our venturi scrubber features a wetted wall inlet that eliminates wet-dry build-up. Distributing the scrubbing liquid over a inlet perimeter of the venturi (Weir) eliminates the use of spray nozzles any potential for plugging. Downstream of the venturi an efficient entrainment separation is accomplished using either a mist eliminator or a cyclonic separator

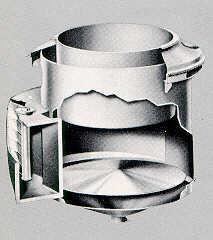

The 3 sections of a Ducon Venturi scrubber are converging, throat, and diverging sections. Inlet gas stream enters the scrubber at the converging section. As the gas cycles down to the throat it increases speed causing liquid from the walls to tear into tiny droplets. These tiny liquid droplets entrain particles. Downstream particle removal happens in the diverging section as the gas is forced to slow down. A Venturi Scrubber can be engineered to collect both particulate and gas pollutants. That being said, the most efficient use of a Venturi Scrubber is to remove particles. Packed towers, FGD, and other scrubber technology are more efficient at removing gas pollutants.

Venturi Scrubber Advantages

- Over 99.9% + collection efficiency into sub-micron range

- No wet-dry build-up

- Venturis up to 80 in. of pressure drop available to remove sub-micron particulate

- Adjustable venturi throat available (manual or automatic)

- No spray nozzles or distribution jets to eliminate plugging

- Slurries with high solids can be recycled

- Non-clogging

- Water level control not required

- Handles high inlet gas temperatures and particulate levels

- Optional packed tower section: for gas absorption

- Various construction materials such as Inconel, Hastelloy, 317L

- S.S., and FRP available: for corrosive applications

Ventri-Rod Scrubber is an excellent choice for any business that is looking to go green and reduce its environmental impact. These devices use a unique system design to scrub the air clean, without using any harmful chemicals or pollutants. This makes them safe for both your employees and the environment!

Not only are Ventri Rod Scrubbers environmentally friendly, but they're also incredibly effective at cleaning the air. In fact, they can remove up to 99% of airborne pollutants! This means that your facility will be cleaner and safer for everyone who works there.

Ducon Venturi Scrubber For Maximum Collection Efficiency & Minimum Maintenance

The Ducon Vertical Venturi Oriclone (Type VVO), Venturi Scrubber is a high energy, high efficiency dust and fume collector designed to bring dust-laden gas into intimate contact with the scrubbing liquid by means of acceleration and turbulence in a venturi throat.

These scrubbers are designed for maximum efficiency and are ruggedly constructed for long service life with minimum maintenance.

Although the Ducon Oriclone Venturi Scrubber Type VVO is included as a standard item of equipment in our line of gas scrubbers, it resists standardization and requires more of the "custom-designed” approach. Decisions on liquid feed, venturi throat design, construction materials, etc. must be based on the specific operating conditions. In some cases, several types of materials or combinations thereof (alloys, fiberglass reinforced polyester, epoxy coated or rubber-lined steel) may be the most practical selection to withstand the conditions of corrosion and/or erosion. The use of

(1) an integral recycle tank for scrubbing liquid feed to the venturi;

(2) precooler at the inlet of the venturi to properly condition high temperature gases;

(3) after-cooler section, must be carefully considered in order to achieve sound and practical equipment design and satisfactory performance.

Our many years of experience in application and design engineering in this field enables us to provide this service.

The collection efficiency of the Ducon Oriclone Venturi Scrubber is a function of the pressure drop across the throat which, in turn, is a function of the quantity of submicron particulate matter suspended in the gas stream. Type VVO scrubbers can be supplied to operate at pressure drops from 8” to 60” W.G. or higher.

For applications requiring the maintenance of a predetermined pressure drop level for varying inlet volumes, the Type VVO Scrubber can be provided with an adjustable throat mechanism. This feature also permits adjustment of pressure drop to upgrade collection efficiency to meet increased process or code requirements.